Induction Soldering connectors together Class: Induction Soldering

Induction Soldering connectors together Class: Induction Soldering Intro: Soldering connectors together Objective Soldering two connectors simultaneously to a tin plated copper ground plateMaterial Tin plated copper ground plate 4” x 1.75” (101.6mm x 44.45mm), 2 connectors, one with12 pins & one with 4 pins and 60/40 …

Induction Soldering stainless steel Class: Induction Soldering

Induction Soldering stainless steel Class: Induction Soldering Intro: Soldering stainless steel Objective Heat Stainless steel connector for soldering application in automotive wire harness manufacturingMaterial Stainless steel connector 1.57” (40mm) long, 0.6” (15mm) OD & 0.4” (10mm) thick. Lead free solderTempe…

Induction Soldering LED to aluminum housing Class: Induction Soldering

Induction Soldering LED to aluminum housing Class: Induction Soldering Intro: Soldering LED to aluminum housing Objective Heat an aluminum spotlight housing to solder an LED assembly to the inside baseMaterial LED housing with copper plug, aluminum spotlight housing 5” (127mm) dia at top, 1.25” (31.75mm) dia at base, temperat…

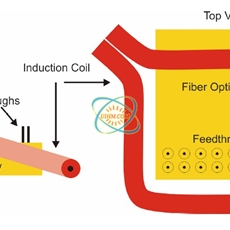

Induction Soldering Glass Feedthroughs Class: Induction Soldering

Induction Soldering Glass Feedthroughs Class: Induction Soldering Intro: Soldering Glass Feedthroughs Objective Heat a kovar fiber optic housing with glass feed-throughs to 400F (204.4C) within 20 seconds for a soldering application, to form a hermetic seal Material Kovar housing with 18 glass feed-throughs, solder preform…

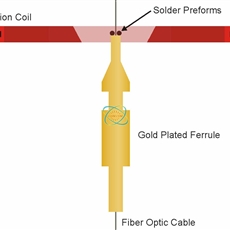

Induction Soldering Ferrule to Fiber Optic Cable Class: Induction Soldering

Induction Soldering Ferrule to Fiber Optic Cable Class: Induction Soldering Intro: Soldering Ferrule to Fiber Optic Cable Objective To heat a gold-plated ferrule and fiber optic cable to 475F within 8 seconds for a soldering applicationMaterial Gold-plated ferrule tube, fiber optic cable, solder preformTemperature 475 FFrequency 270…

Induction Soldering Fiber Optic Class: Induction Soldering

Induction Soldering Fiber Optic Class: Induction Soldering Intro: Soldering Fiber Optic Objective To heat a fiber optic housing to 400F within 10 seconds for avsoldering application, to form a hermetic sealMaterial Gold-plated aluminum housing, solder preform ring and fluxTemperature 400 FFrequency 267 kHzEquipment …

Induction soldering solar panel Class: Induction Soldering

Induction soldering solar panel Class: Induction Soldering Intro: soldering solar panel Objective Heat multiple joints on solar flex circuit strips to 500F (260C) within ten seconds for a soldering application.Material Flexible solar panel, Solder Plus Paste 63NC-A, 0.0625” (1.59mm) thick Teflon sheetsTemperature 5…

Induction Soldering brass rings Class: HF Induction Brass Solder

Induction Soldering brass rings Class: HF Induction Brass Solder Intro: Soldering brass rings Objective: To heat 1 3/4, 3 and 6 diameter brass slip rings and a sheathed copper wire assembly to 3600 F for soldering within three (3) to six (6) seconds. Currently production is accomplished by using a soldering iron and stick…

Induction Soldering Brass Bellows Assembly Class: HF Induction Brass Solder

Induction Soldering Brass Bellows Assembly Class: HF Induction Brass Solder Intro: Soldering Brass Bellows Assembly Objective: To heat a brass bellows and end cap assembly to 450F for soldering within 20 seconds. Presently, a soldering iron is used to produce the joint between the bellows and cap. The customer requests a quality sol…

Induction Soldering brass tubes Class: HF Induction Brass Solder

Induction Soldering brass tubes Class: HF Induction Brass Solder Intro: Soldering brass tubes Objective: Soldering two brass tubes measuring 3/4 and 1/4 together for use as cellular phone antennas. The lengths of tubes range from four (4) feet to twelve (12) feet, and must be soldered along the axial side. The joint is to…

Recommended

Air Cooled clamp coil (half-open coil) for preheating gas pipeline

U shape air cooled induction coil by UM-100C-HF for pipeline preheating

induction brazing diamond segment

induction melting for crystal growth

induction unassemble 2Ton guard ring of turbine

induction preheating D5000mm end ring for welding by 2 UM-DSP80A-HF at the same time

induction preheating D1219mm pipeline for welding by UM-DSB80AB-MF air cooled induction heater and i

induction preheating and heat treatment for 18Ton control valve of 600MW turbine