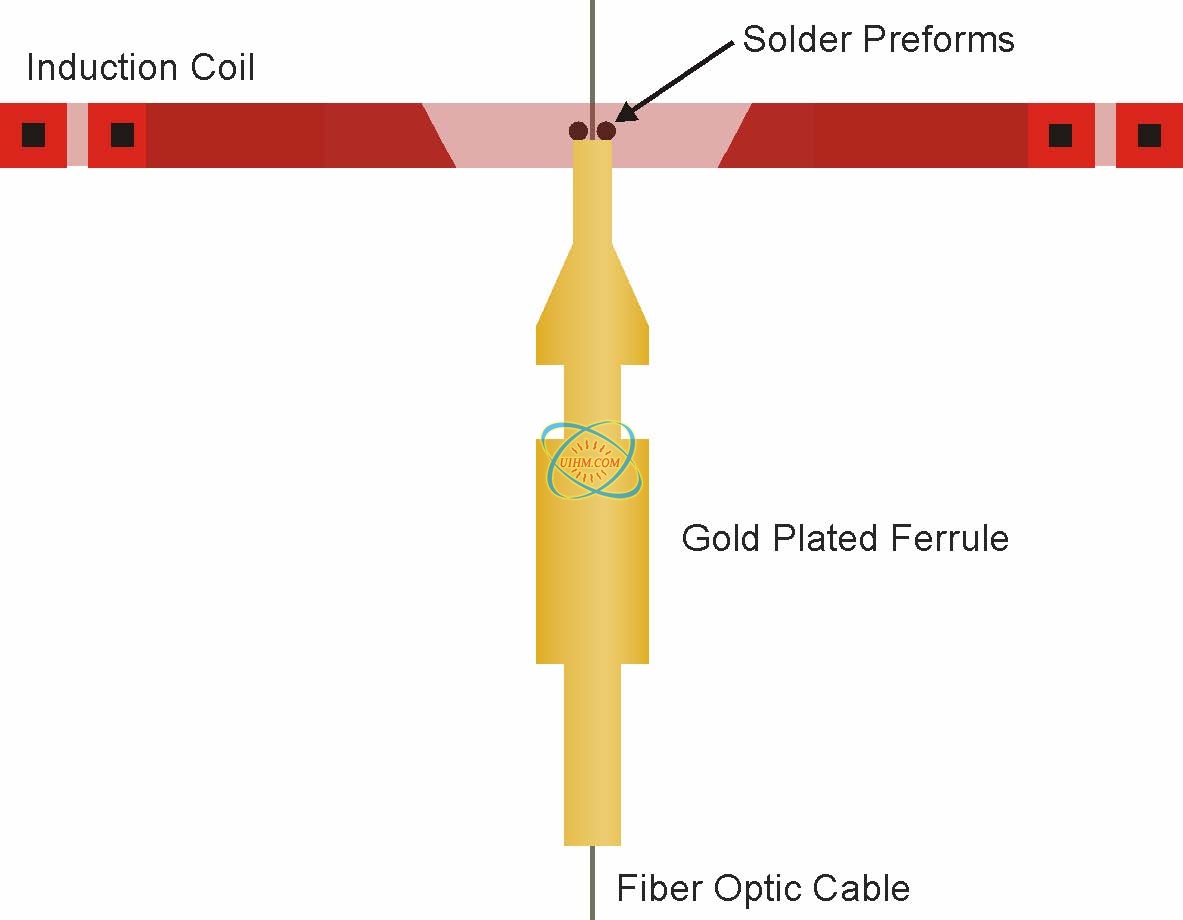

Induction Soldering Ferrule to Fiber Optic Cable

Views Send Enquiry

Objective To heat a gold-plated ferrule and fiber optic cable to 475°F within 8 seconds for a soldering application

Material Gold-plated ferrule tube, fiber optic cable, solder preform

Temperature 475 ºF

Frequency 270 kHz

Equipment Power of 6kW power supply with a specially designed induction coil.

Process A specially designed, two-turn plate concentrator coil was used to provide uniform heat to the fiber optic assembly. The assembly was placed in a specially designed fixture, then placed inside the induction coil. RF power was applied until the solder flowed and created a solid joint.

Results Consistent and repeatable results were achieved using the Power of 6 kW power supply and induction coil with a 5 to 7 second heat cycle, depending on the type of solder used (see solder chart below). Solder Heat Cycle

Soldering Ferrule to Fiber Optic Cable

Related Content

Air Cooled clamp coil (half-open coil) for preheating gas pipeline

induction coating by air cooled clamp induction coil

Remove plastic coating from steel tubes by Induction Heating

Releasing Fixture by Induction Heating

U shape air cooled induction coil by UM-100C-HF for pipeline preheating

induction quenching with custom-design inductor

induction brazing diamond segment

induction brass soldering copper plate_2

Newest Comment

No Comment

Post Comment