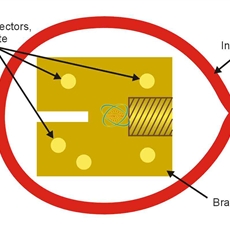

Induction Soldering Steel Connectors Class: Induction Soldering

Induction Soldering Steel Connectors Class: Induction Soldering Intro: Soldering Steel ConnectorsObjective Heat an assembly of small, gold-plated steel connectors to a brass block.Material Approx. 1/8” (3.2mm) diameter gold-plated steel connectors, 1”(25.4mm) square x 1/4” thick brass blockTemperature 600F(315.6C)Freq…

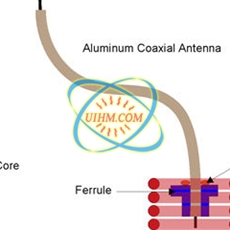

Induction Soldering Radio Antenna Class: Induction Soldering

Induction Soldering Radio Antenna Class: Induction Soldering Intro: Soldering Radio AntennaObjective To heat a coaxial antenna assembly to 600F within 2 seconds for a soldering application. The goal to improve on an existing procedure with a soldering iron which required 10 to 15 seconds.Material .250” diameter alumi…

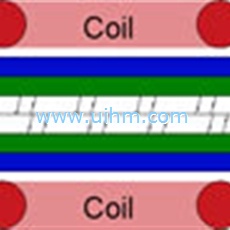

Induction Solder Flex Circuits Class: HF Induction Brazing

Induction Solder Flex Circuits Class: HF Induction Brazing Intro: Solder Flex Circuits Objective To heat multiple joints on flex circuit strips to 180-200F within seven seconds for a soldering application.Material Copper bonded to polyester flex circuit strips, Solder Plus Paste 63NC-A, 0.0625” thick Teflon sheetsT…

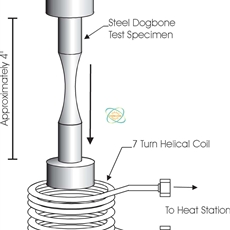

Induction Heating Steel Dogbone Specimen Class: Other Induction Applications

Induction Heating Steel Dogbone Specimen Class: Other Induction Applications Intro: Heating Steel Dogbone Specimen Objective: To heat a magnetic steel dogbone specimen to 12000F as quickly as possible and sustained for tensile testing. Heating should take place using a helical coil placed square in relation to the long axis of the ga…

Induction Heating Repair Lined Steel Tank Class: Other Induction Applications

Induction Heating Repair Lined Steel Tank Class: Other Induction Applications Intro: Heating Repair Lined Steel Tank Objective: To heat selected areas of a glass lined steel tank to 16000F in order to perform repairs of cracks and chips. The glass is used as a frit which must be reflowed and filled into the damaged areas. Temperature …

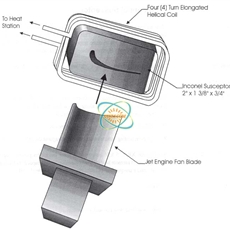

Induction Heating Inconnel Susceptor Class: Other Induction Applications

Induction Heating Inconnel Susceptor Class: Other Induction Applications Intro: Heating Inconnel Susceptor Objective: Heat an Inconnel susceptor to 19500F in less than one (1) minute for heating jet engine fan blades. This approach is to be used, instead of directly heating the blade, since improved temperature uniformity will be…

Induction Heat Television Picture Tube Glass Class: HF Induction Brazing

Induction Heat Television Picture Tube Glass Class: HF Induction Brazing Intro: Heat Television Picture Tube Glass Objective: The incorporation of solid state RF induction heating into the television picture tube industry, specifically the insertion of attachment pins into the already formed picture tube glass panel. Four pins ar…

Induction Shrink Fitting Cam Shaft Gears Class: Induction Shrink Fitting

Induction Shrink Fitting Cam Shaft Gears Class: Induction Shrink Fitting Intro: Shrink Fitting Cam Shaft Gears Objective To heat aluminum and steel camshaft gears to over 500F within 4 minutes for a shrink fitting application.Material 6” diameter, 2” thick steel and aluminum camshaft gears, “K” type thermocouple, digital ther…

Induction Shrink fit steel ring Class: Induction Shrink Fitting

Induction Shrink fit steel ring Class: Induction Shrink Fitting Intro: Shrink fit steel ring Objective Heating a steel band to 1000 F (538 C) and inserting a carbon graphite ring in the center of the steel bandMaterial 4340 steel ring 8” (20.3cm) OD x 7.75” (19.7cm) ID, .895” (22.7mm) thick, carbon graphite ring inser…

Induction Shrink Fit Bearings Class: Induction Shrink Fitting

Induction Shrink Fit Bearings Class: Induction Shrink Fitting Intro: Shrink Fit Bearings Objective To heat a roller bearing assembly for a shrink fitting applicationMaterial Steel bearings, diameters 1” to 3.5” (25.4 to 89mm)Temperature 300F (150C)Frequency 60 kHzEquipment Power of 25kW solid-state induction power su…

Recommended

Air Cooled clamp coil (half-open coil) for preheating gas pipeline

U shape air cooled induction coil by UM-100C-HF for pipeline preheating

induction brazing diamond segment

induction melting for crystal growth

induction unassemble 2Ton guard ring of turbine

induction preheating D5000mm end ring for welding by 2 UM-DSP80A-HF at the same time

induction preheating D1219mm pipeline for welding by UM-DSB80AB-MF air cooled induction heater and i

induction preheating and heat treatment for 18Ton control valve of 600MW turbine