Induction Annealing Tungsten Rods Class: HF Induction Annealing

Induction Annealing Tungsten Rods Class: HF Induction Annealing Intro: Objective To heat customer-supplied rods of various diameters (0.14 inch to 0.49 inch) to 4170F (2300C) at 2-4 feet per minuteMaterial Tungsten and Molybdenum; Tests are run in an atmosphere of Nitrogen or Hydrogen avoid oxidation of the materials.Tempera

Induction Annealing Titanium fasteners Class: HF Induction Annealing

Induction Annealing Titanium fasteners Class: HF Induction Annealing Intro: Objective Heating a titanium fastener to 1100-1450F (593-788C) for an annealing process.Material 0.06” (1.5mm) high zone on a titanium fastener measuring 0.163-0.375” (4.14-9.52mm) in diameter and 0.5-3.0” (12.7-76.2mm) in lengthTemperature 1100-1450F (…

Induction Annealing Brazing Wire Class: HF Induction Annealing

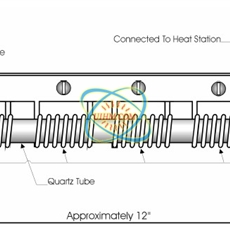

Induction Annealing Brazing Wire Class: HF Induction Annealing Intro: Objective: Anneal a brazing wire for preform production.Material :Copper Nickel Silver 2774 Alloy rod 0.070″ (1.8mm) diameter.Temperature 650F(343.3C)Frequency 281 kHzEquipment • UM-06A-UHF induction heating system equipped with a remote workhead with on…

Induction Annealing Thread Ring Class: HF Induction Annealing

Induction Annealing Thread Ring Class: HF Induction Annealing Intro: Objective:To selectively and uniformly anneal two sections of a thread ring gage block from the hole to the outside surface from a hardness of Rc 59-61 to Rc 45. The gage blocks are made from O6 steel and range in size from 1″ to 8 1/2″ in diameter and r…

Induction Bending And Hot Rolling Class: Induction Thermal Treatment

Induction Bending And Hot Rolling Class: Induction Thermal Treatment Intro: Induction Bending And Hot Rolling the 1620mmX40mm steel pipe in the West-East natural gas transmission project.Induction bending is also referred to as hot rolling, but there are some differences between the two processes. Induction bending is an efficien

Induction surface Quenching works Class: HF Induction Quenching

Induction surface Quenching works Class: HF Induction Quenching Intro: Induction quenching is the process of quenching steel by heating it. It is done by an alternating magnetic field to a temperature above or within a specific transformation range. It is straight away followed by quenching. This procedure of quenching can b

Heat Treatment Techniques and Principles Class: Induction Heating for Aerospace

Heat Treatment Techniques and Principles Class: Induction Heating for Aerospace Intro: heat-treatment1Heat Treatment is generally referred to as heating and cooling of different metals in a controlled way in order to amend both of its mechanical and physical properties without altering the shape of the product. The process involves the mate

Annealing An Effective Heating Process Class: HF Induction Annealing

Annealing An Effective Heating Process Class: HF Induction Annealing Intro: There are different types of heat treatment procedures offered by various companies in the market. Few of them are widely applied and are extremely effective. One of the efficient heat treatment procedures is annealing. This process supports an entire ind

Induction Furnace Cost effective and energy efficient Class: High Capacity Melting

Induction Furnace Cost effective and energy efficient Class: High Capacity Melting Intro: Raising the temperature of the items break down the complexity of the matter and simplifies the tedious process. Heating melts the hard structure of the substances and minutest of the details can be analyzed.There are many alluring shapes of hard metals.

Induction Heat Treatment Services Class: Induction Thermal Treatment

Induction Heat Treatment Services Class: Induction Thermal Treatment Intro: Induction-Heat-Treatment-ServicesShot blasting is creating depressions on the surface of a metal by regularly pelting it with shots of sand or steel balls of a certain diameter. The process is accomplished by employing something like an air gun. A shot bl

Recommended

Air Cooled clamp coil (half-open coil) for preheating gas pipeline

U shape air cooled induction coil by UM-100C-HF for pipeline preheating

induction brazing diamond segment

induction melting for crystal growth

induction unassemble 2Ton guard ring of turbine

induction preheating D5000mm end ring for welding by 2 UM-DSP80A-HF at the same time

induction preheating D1219mm pipeline for welding by UM-DSB80AB-MF air cooled induction heater and i

induction preheating and heat treatment for 18Ton control valve of 600MW turbine