Induction Silver soldering with induction heating Class: Induction Soldering

Induction Silver soldering with induction heating Class: Induction Soldering Intro: Silver soldering with induction heating A full treatise on silver soldering (otherwise known as hard soldering) would be an extensive document, and all I want to cover here is the basics. A serious job such as constructing a model locomotive boiler re…

Induction Melting Gold and Silver Class: Rare Metals Melting

Induction Melting Gold and Silver Class: Rare Metals Melting Intro: Melting Gold and Silver Everything for Gold and Silver Melting, it used to be that when melting gold, people used a blow torch, then a torch, then an electric melter and then an induction melter. Whatever your choice, we have the torch, the electric m…

Induction Bin Brazing Class: HF Induction Brazing

Induction Bin Brazing Class: HF Induction Brazing Intro: Bin Brazing Pin Brazing forms part of a technology developed in Sweden throughout the latter half of the 20th century by AGA. The purpose, for attaching current carrying cables to what were deemed Sensitive Substrate Materials, or in this case Railroa…

Induction Fusing the butt joint Class: Induction Jointing

Induction Fusing the butt joint Class: Induction Jointing Intro: Fusing the butt joint Objective Fuse elastomer (TPE) tubes together in two ways, as a butt joint and as a overlap joint.Material PeBax tubing 3/16” (4.76) OD, 1/8” (3.18 mm) ID and slightly largerStainless steel Teflon coated mandrel 1/8” (3.18 mm)…

Induction Heating brass mandrel die Class: HF Induction Brass Solder

Induction Heating brass mandrel die Class: HF Induction Brass Solder Intro: Heating brass mandrel die Objective Water-cooled brass mandrel die, nylon LDPE catheter, “K” type thermocouple and temperature controller.Material materials, supplies involved in the applicationTemperature 400F (204C)Frequency 325kHzEquipment Power …

Induction Heating steel mandrel tip Class: Induction Heat Treatment

Induction Heating steel mandrel tip Class: Induction Heat Treatment Intro: Heating steel mandrel tip Objective Heat a water-cooled steel mandrel to 700F (371C) to form a high quality Teflon catheter tip.Material Teflon catheter tubing, mandrel assemblyTemperature 600-700F (315-371C)Frequency 376 kHzEquipment • Power of 10kW…

Induction Heating Catheter Tipping Die Class: Induction Heat Treatment

Induction Heating Catheter Tipping Die Class: Induction Heat Treatment Intro: Heating Catheter Tipping Die Objective: To heat an aluminum catheter tipping die to above 2850F within 2 to 5 seconds for the forming of catheter material. Presently, heating is performed in 15 seconds with older induction equipment. The customer woul…

Induction Heating fan blades for welding Class: Induction Welding

Induction Heating fan blades for welding Class: Induction Welding Intro: Heating fan blades for welding Objective To uniformly heat jet engine turbine fan blades to 1800F (982.2C) within five minutes for a welding applicationMaterial Jet engine turbine fan blades with 2”(50.8mm) length tipTemperature 1800F (982.2C)Frequen…

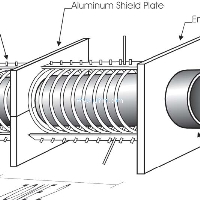

Induction Soldering Co-axial Wire Class: Induction Soldering

Induction Soldering Co-axial Wire Class: Induction Soldering Intro: Soldering Co-axial Wire Objective To solder center-conductor and shielding braid of wireassemblies to 500 (250) F(C).Material • Customer-supplied assemblies• Temperature indicating paint• Flux-cored solder wireTemperature 500 (250) F (C)Frequency 2…

Induction Soldering wires onto connector Class: Induction Soldering

Induction Soldering wires onto connector Class: Induction Soldering Intro: Soldering wires onto connector Objective Heat connector assemblies for solderingMaterial Device assemblyTin plated brass terminals Solder pasteTemperature 500F (260C) 5-7 secondsFrequency 360 kHzEquipment Power of 6 kW induction heating system equippe…

Recommended

induction brazing diamond segment

induction shrink fitting for Automotive cylinder rod

induction heating drill pipe by twin coils

Ball stud high-frequency induction hardening

Splined shaft induction hardening

Sprocket induction hardening

Gear shaft induction hardening

High frequency induction brazing welding steel bar