induction brazing diamond segment Class: HF Induction Brazing

induction brazing diamond segment Class: HF Induction Brazing Intro: Induction Brazing is joining of similar or dissimilar metal (parent materials) by using heat and braze material (filler material) whose melting temperture is normally above 500 C and below the melting temperature of parent materials being joined.Induction

Induction Curing Adhesive for Steel Motor Shaft Class: Induction Tempering or Preheating

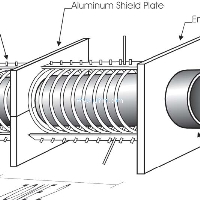

Induction Curing Adhesive for Steel Motor Shaft Class: Induction Tempering or Preheating Intro: • UM-60AB-RF induction heating system equipped with a remote workhead enclosure for double capacitor/buss modules. Zone 1 needs a 0.25 μF capacitor, while Zone 2 requires 0.66 μF• An induction heating coil designed and developed specifically (half open)

induction heating L shape steel with L shape induction coil Class: Induction Heat Treatment

induction heating L shape steel with L shape induction coil Class: Induction Heat Treatment Intro: Objective: quick induction heating L shape steel for Material: stainless steelTemperature: 800 CFrequency: 60 KHzEquipment: UM-40AB-HFResults/Benefits: Induction heating provides:• Minimal contamination of conductive material during manufacturing• Quick …

induction shrink fitting for Automotive cylinder rod Class: Induction Shrink Fitting

induction shrink fitting for Automotive cylinder rod Class: Induction Shrink Fitting Intro: Induction shrink fitting refers to the use of induction heater technology to pre-heat metal components between 150 C (302 F) and 300 C (572 F) thereby causing them to expand and allow for the insertion or removal of another component. Typically the lower

induction melting steel for casting Class: Induction Melting

induction melting steel for casting Class: Induction Melting Intro: induction melting steel for casting

Frequency induction heating equipment and quenching machine stainless steel quenching Class: HF Induction Quenching

Frequency induction heating equipment and quenching machine stainless steel quenching Class: HF Induction Quenching Intro: Our UM-100AB-RF super audio induction heating equipment and quenching machine on the quenching diameter 70mm, length 600mm shaft quenching, material: 45 #, hardness depth of 2 mm, hardness 50HRC quenching produced axis has a uniform surface hardness,less

High Frequency induction heating equipment annealed stainless steel tube Class: HF Induction Annealing

High Frequency induction heating equipment annealed stainless steel tube Class: HF Induction Annealing Intro: UM-60AB-HF high frequency induction heating equipment for stainless steel pipe annealing (solution), annealed steel pipe weld can withstand the stress of bending, flattening, the weld will not crack, fast heating and high efficiency

induction Hardening applications Class: Induction Hardening

induction Hardening applications Class: Induction Hardening Intro: UIHM induction surface hardening applications one application: under torsion and bending load of the alternating workpieces requiring surface layer under the Ministry of higher stress than the heart or abrasion on the surface to be made to strengthen the

induction heating drill pipe by twin coils Class: Induction Jointing

induction heating drill pipe by twin coils Class: Induction Jointing Intro: Induction heating is often used in the heat treatment of metal items. The most common applications are induction hardening of steel parts, induction soldering/brazing as a means of joining metal components and induction annealing to selectively soften an

induction heating inner surface and quenching Class: Other Induction Applications

induction heating inner surface and quenching Class: Other Induction Applications Intro: induction heating inner surfaceinduction quenchingrapid induction heating

Recommended

induction brazing diamond segment

induction shrink fitting for Automotive cylinder rod

induction heating drill pipe by twin coils

Ball stud high-frequency induction hardening

Splined shaft induction hardening

Sprocket induction hardening

Gear shaft induction hardening

High frequency induction brazing welding steel bar