ultra high frequency induction brazing works Class: HF Induction Brazing

ultra high frequency induction brazing works Class: HF Induction Brazing Intro: Ultra high frequency (>400KHz) induction heating technology are widely used in brazing tiny workpiece, it can also used for quick brazing or jointing work as high frequency bring a faster heating speed.ultra high frequency induction brazing stainless s

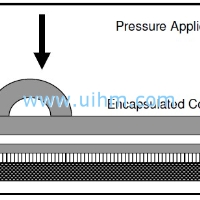

Induction Bonding Solar Panel Shingles Class: Induction Bonding

Induction Bonding Solar Panel Shingles Class: Induction Bonding Intro: Objective To heat the stainless steel substrate of a solar panel shingle in order to melt the polymer encapsulant, allowing two shingles to bond together with a 3 inch overlap.Material 3" by 10.25" section of a 21" solar panel shingleTemper

Induction bonding Metal to plastic Class: Induction Bonding

Induction bonding Metal to plastic Class: Induction Bonding Intro: Objective: Bond an aluminium mesh to a plastic beer kegMaterial : Aluminium mesh. Plastic keg 320 mm (12.5”) IDTemperature 250 oC (482 oF)Frequency 200 kHzEquipment UM-10AB-UHF, induction heating system, equipped with a remote workhead containing two .33μ

induction heating inner surface Class: Other Induction Applications

induction heating inner surface Class: Other Induction Applications Intro: Some application need to heat inner surface, we can use a special induction coil with magnetic core to satisfy this work.inner induction coil heating inner surface

Induction Saw blade brazing & welding Class: HF Induction Brazing

Induction Saw blade brazing & welding Class: HF Induction Brazing Intro: Induction Brazing is joining of similar or dissimilar metal (parent materials) by using heat and braze material (filler material) whose melting temperture is normally above 500 C and below the melting temperature of parent materials being joined.Induction

induction melting with vacuum furnace Class: Induction Melting

induction melting with vacuum furnace Class: Induction Melting Intro: Induction melting is often used for vacuum melting. Some applications such as melting gold or titanium or platinum need a vacuum furnace to avoid oxidation, induction melting is a very good method for these work.UIHM can provide induction heating machines

Induction Annealing an oval cut out on a stainless steel tube Class: HF Induction Annealing

Induction Annealing an oval cut out on a stainless steel tube Class: HF Induction Annealing Intro: Objective To anneal a area around an oval cutout on a stainless steel tube prior to extrusionMaterial:.75" (19mm), 1.5" (38.1mm) and 4" (101.6mm) diameter steel tubesTemperature: 1900 F ( 1038 C)Frequency: 50KHzEquipment:• UM-60AB-HF induct

Applications of UM induction heating equipment Class: Other Induction Applications

Applications of UM induction heating equipment Class: Other Induction Applications Intro: Induction heating is a method of providing fast, consistent heat for manufacturing applications which involve bonding or changing the properties of metals or other electrically-conductive materials. The process relies on induced electrical currents within

Retsch Evacuable Dies for Pellet Press PP Class: Induction Heat Treatment

Retsch Evacuable Dies for Pellet Press PP Class: Induction Heat Treatment Intro: Induction heating can produce high power densities which allow short interaction times to reach the required temperature. This gives tight control of the heating pattern with the pattern following the applied magnetic field quite closely and allows reduce

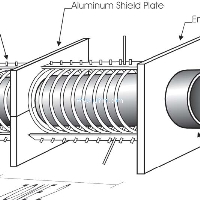

induction Epitaxial growth of silicon(IGBT-100KW-20KHz) Class: Other Induction Applications

induction Epitaxial growth of silicon(IGBT-100KW-20KHz) Class: Other Induction Applications Intro: induction Epitaxial growth of silicon(IGBT-100KW-20KHz)Induction heating can produce high power densities which allow short interaction times to reach the required temperature. This gives tight control of the heating pattern with the pattern following the

Recommended

induction brazing diamond segment

induction shrink fitting for Automotive cylinder rod

induction heating drill pipe by twin coils

Ball stud high-frequency induction hardening

Splined shaft induction hardening

Sprocket induction hardening

Gear shaft induction hardening

High frequency induction brazing welding steel bar