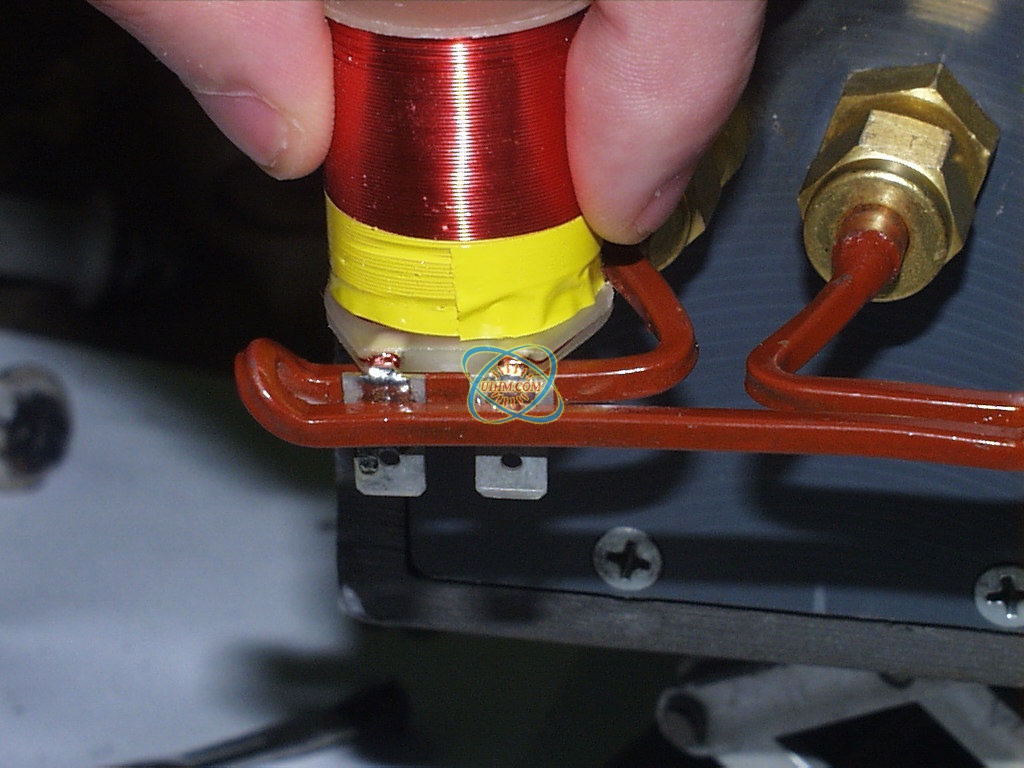

Induction Soldering wires onto connector

Views Send Enquiry

Objective Heat connector assemblies for soldering

Material Device assembly

Tin plated brass terminals Solder paste

Temperature 500°F (260°C) 5-7 seconds

Frequency 360 kHz

Equipment Power of 6 kW induction heating system equipped with a remote heat station, containing two 0.66 μF capacitor.

An induction heating coil designed and developed specifically for this application.

Process A single turn helical coil is used to heat the solder paste. The

connectors are placed inside the induction heating coil and RF power is applied for 5-7 seconds until the connector heats.

Solder paste is applied to the joint in two ways, stick-fed or manually.

Results/Benefits • Compared to using a manual soldering iron, induction

heating precisely applies heat to for higher quality solder joints

• This is ideal for integrating with an automated system. By stick- feeding the solder more aesthetically pleasing parts are produced.

Soldering wires onto connector

Related Content

Air Cooled clamp coil (half-open coil) for preheating gas pipeline

induction coating by air cooled clamp induction coil

Remove plastic coating from steel tubes by Induction Heating

Releasing Fixture by Induction Heating

U shape air cooled induction coil by UM-100C-HF for pipeline preheating

induction quenching with custom-design inductor

induction brazing diamond segment

induction brass soldering copper plate_2

Newest Comment

No Comment

Post Comment