-

Keywords"or",total

1005 records

-

induction soldering connectors together

Soldering connectors together Objective Soldering two connectors simultaneously to a tin plated copper ground plateMaterial Tin plated copper ground plate 4” x 1.75” (101.6mm x 44.45mm), 2 connectors, one with12 pins & one with 4 pins and 60/40 solde…

-

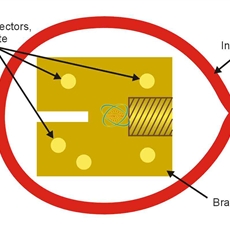

induction soldering steel connectors

Soldering Steel Connectors Objective Heat an assembly of small, gold-plated steel connectors to a brass block. Material Approx. 1/8” (3.2mm) diameter gold-plated steel connectors, 1”(25.4mm) square x 1/4” thick brass block Temperature 600F(315.6C)…

-

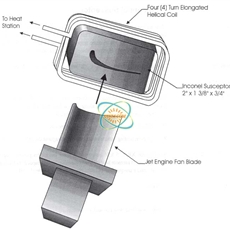

induction heating inconnel susceptor

Heating Inconnel Susceptor Objective: Heat an Inconnel susceptor to 19500F in less than one (1) minute for heating jet engine fan blades. This approach is to be used, instead of directly heating the blade, since improved temperature uniformity will be achi…

-

induction melting aluminum for casting

Objective Heating a graphite crucible to 1292F (700C) to melt aluminum to liquid form for a casting applicationMaterial 9.8” (250mm) OD, 22.4” (570mm) long, 0.7” (17.5mm) thick Graphite crucible, approx. 92.5lb (42kg) of aluminumTemperature 1292 F (700C…

-

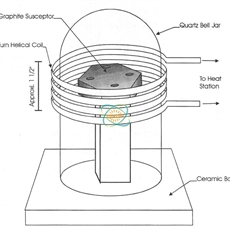

induction heating graphite susceptor

Heating Graphite Susceptor Heating Graphite SusceptorObjectiveTo Heat a graphite susceptor to 1100C in an inert atmosphere of Nitrogen and Hydrogen. The susceptor is to be used for metal oxide chemical vapor deposition (MOCVD) crystal growth experiments. V…

-

induction hot forming titanium rod

Objective To heat a titanium rod to 1700F (926.7C) within 60 seconds for hot forming. Material Titanium rods, 1.25”(31.8mm) diameter, 5”(127mm) length Temperature 1700F (926.7C) Frequency 70 kHz Equipment • Power of 60kW induction heating system, eq…

-

induction stainless steel hot forming

Objective: To heat a stainless steel “J” tape to 3000F from room temperature at a rate of 15 feet per minute. The material is to be heated to aid in forming the “J” shape from flat stock. Material: Stainless Steel “J” Tape measuring 0.562″ wide, 0.…

-

induction melting glass for fiber drawing

Objective To heat a metal susceptor vessel to 2200F within 25 minutes for a fiberglass melting application Material Metal susceptor vessel Temperature 2200F Frequency 300KHZ Equipment Power of 60 kW RF power supply, remote heat statio…

-

induction forge steel rods

Objective To heat the ends of steel rods to 1800F prior to a forging operation. Processing of the rods includes heating, pressing in a two part die to forge the push rod end, and a final heating in a channel coil to temper the rods and relieve the forging …

-

induction hardening steel screw threads or steel nails

ObjectiveHeat steel roofing screw to 1650 F to harden the threadsMaterial Steel roofing screws of varying diameters less than 1.25” (31.75mm) diameter, 5” (127mm) longTemperature:1650 F (899 C)Frequency:291 kHzEquipment • Power of 6 kW induction heating…