Induction Hardening steel screw threads or steel nails

Views Send Enquiry

ObjectiveHeat steel roofing screw to 1650 ºF to harden the threads

Material Steel roofing screws of varying diameters less than 1.25” (31.75mm) diameter, 5” (127mm) long

Temperature:1650 ºF (899 ºC)

Frequency:291 kHz

Equipment

• Power of 6 kW induction heating system, such as UM-05AB-UHF,UM-06AB-UHF, equipped with a remote work head containing two 0.33μF capacitors for a total of 0.66μF

• An induction heating coil designed and developed specifically for this application.

Process A five turn helical coil is used heat the screw threads. The screw is placed in the coil, heat is applied for 8 seconds to achieve a 2” long zone at the required hardness.

Results/BenefitsInduction heating provides:

• Very rapid heating, faster production rates, efficient

• Ability to incorporate into existing production lines

• Repeatable, consistent results

• Even distribution of heating

Related Content

induction hardening surface of steel plate

induction hardening gear surface

induction quenching surface of engine part to 0.1mm depth by 300KW UHF induction heaters

induction quenching brake flange by 200KW UHF induction heater

induction quenching brake disk of automobile by UHF induction heater

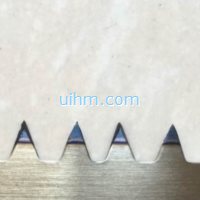

induction quenching bandsaw teeth by UHF induction heater

induction quenching axle by UHF induction heating machine

induction quenching axle by UHF induction heater

Hot

induction hardening surface of steel plate

induction hardening gear surface

induction hardening wheel gears

induction hardening TCT knife (tungsten carbide tool)

induction hardening knife edge (sickle blade)

induction hardening inner surface of steel pipe

induction hardening inner surface of steel ring by UHF induction heater

induction hardening inner surface of gear

Newest Comment

No Comment

Post Comment