tubular Induction brazing wires

2013/5/16 Views

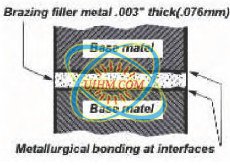

Made from seamless tubular wire This ensures consistent flux to wire ratio and is especially important in the fabrication of pre-forms.

Competitors' products are made from folded sheets and flux may be lost during fabrication or during transport.

Our flux cored tubular brazing wires are made from seamless tubes, hence no loss of flux.

Less flux required

There is no loss of flux or unnecessary used flux as the needed quantity is adapted to the filler metal consumption.

Less labour required

Traditional applications require that the flux has to be applied first and then the wire or rod. By combining flux and filler metal only one process step is required,

saving both time and effort. Improved quality of work

Improved quality of work

Competitors' products are made from folded sheets and flux may be lost during fabrication or during transport.

Our flux cored tubular brazing wires are made from seamless tubes, hence no loss of flux.

Less flux required

There is no loss of flux or unnecessary used flux as the needed quantity is adapted to the filler metal consumption.

Less labour required

Traditional applications require that the flux has to be applied first and then the wire or rod. By combining flux and filler metal only one process step is required,

saving both time and effort.

Improved quality of work

Improved quality of work

The constant flux to wire ratio of our tubular brazing wires reduces wastage of both materials in the production process and assures a better quality of the joints.

Our clients have reported better efficiency and a better quality output.

No post-braze cleaning required

Our tubular brazing wires contain non-corrosive flux.

As a result there is no cleaning required after brazing.

L6 Less water treatment cost Without post-braze cleaning, there is also less water contamination which decreases your company's water treatment costs.

Jl Increased savings = more profit

With our tubular brazing wires, you save time, labour, material and treatment costs. These savings contribute

to increased profit.

Our clients have reported better efficiency and a better quality output.

No post-braze cleaning required

Our tubular brazing wires contain non-corrosive flux.

As a result there is no cleaning required after brazing.

L6 Less water treatment cost Without post-braze cleaning, there is also less water contamination which decreases your company's water treatment costs.

Jl Increased savings = more profit

With our tubular brazing wires, you save time, labour, material and treatment costs. These savings contribute

to increased profit.

Next: induction tempering of steelPrevious: induction PLATING OF STEEL IN VACUUM

Down Attachment

- DownloadAttach1: tubular Induction brazing wires.pdf Clicks

Good

Bad

Newest Comment

No Comment

Post Comment