-

Keywords"car",total

42 records

-

induction brazing carbide to steel shaft

Objective Brazing a cone shaped carbide to a stainless steel shaft for a digger Material Cone shaped carbide 1.12” (28.4mm) dia, 1.5”(38.1mm) tall, stainless steel shaft 1.12” (28.4mm) dia and various length, black brazing flux and braze shims Tempera…

-

induction brazing carbide tip

Objective Braze a carbide tip to a 4140 steel cutting tool Material Carbide Isograde C2 & C5 tips, 4140 circular steel cutter, flux and silver braze shim Temperature 1400 F (760 C) Frequency 290 kHz Equipment • Power of 20kW induction heating syst…

-

induction brazing carbide

Objective Braze a carbide wear pad to steel for automated surgical forceps Material Steel assembly 1/2” (127 mm) long, 1/8 “ (3.175 mm)cross section Carbide wear pad Braze alloy Temperature 1350-1400 F (732- 760 C) Frequency 313 kHz Equipment Po…

-

induction brazing steel-carbide tool

Objective Provide a solution to this steel-carbide brazing applicationMaterial • Body 10mm; carbide tip 57 x 35 x 3 mm• Braze shim• Braze flux whiteTemperature 750C (1382F)Frequency 152 kHzEquipment Power of 10kW induction heating system, equipped with …

-

induction brazing carbide to steel

Objective Braze a carbide sleeve to a steel ‘T’ shank Material 2.0” (51mm) OD carbide sleeve, 1.0” (25.5mm) high braze joint, 1.5 ” (38 mm) steel ‘T’ , 50% silver braze ring Temperature 1292 F (700 C) Frequency 257 kHz Equipment • Power of 10 k…

-

induction brazing carbide teeth to steel pipe

Objective Brazing carbide teeth to a steel jaw in less than 5 minutes Material Steel pipe jaw, 0.5” (12.7mm) dia, 1.25” (31.75mm) long, 0.25” (6.35mm) thick carbide teeth, black flux and silver copper braze shims Temperature 1292F (700C) Frequency 25…

-

induction brazing carbide shaft to steel tube

Objective Braze a carbide shaft to a steel tube Material Carbide shaft 1/8” to 1” diameter (varying sizes) Steel tube 3/8” to 1 ” OD Silver solder braze Temperature indicating paint Temperature 1400 F for 60 seconds Frequency 220 kHz Equipment Pow…

-

induction brazing carbide tool

Objective Braze carbide rotary file assemblies with uniform concentricity in an aerospace application Material • Carbide blank • High speed steel shank • Temperature indicating paint • Braze shim and black flux Temperature 1400F (760C) Frequency …

-

induction brazing carbide tips

Objective Attaching carbide cutters to a steel meat cutter impeller Material carbide blocks; steel shank fitting Temperature 1400 F (760 C) Frequency 219 kHz Equipment Power of 30kW induction heating systems including: Induction heating coil …

-

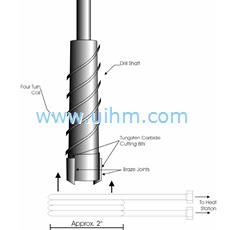

induction brazing carbide tips on drill bits

Objective To braze carbide cutting tips to drill bits ranging in size from 0.5″ to 1.5″ in diameter. The brazing takes place at 1900F and is presently done in 11 seconds for the 0.5″ diameter bit and 39 seconds for the 1.5″ diameter bit. Customer goals…