Induction Soldering circuit boards

Views Send Enquiry

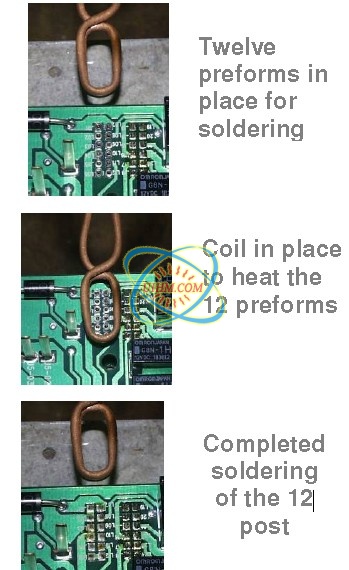

Objective To heat post, lead or lead-free solder preforms for various circuit board soldering applications.

Material Upper and lower circuit boards, small and large lead or lead free preforms.

Temperature < 700 ºF (371ºC) depending on the preform used

Frequency Three turn coil 364 kHz

Small two turn coil 400 kHz

Large two turn coil 350 kHz

Equipment •Power of 6 kW induction heating system, equipped with a remote workhead containing two 0.66μF capacitors for a total of 1.32 μF

• An induction heating coil, designed and developed specifically for this application.

Process Three individual coils are used to heat the various locations on the circuit board depending upon if the location is a single application or a group application. The time varies from 1.8 to 7.5 seconds depending upon location. In production the heat stations and coils are moved into position over the post for

automation purposes. Either lead or lead free solder preforms are used. The process time on the lead free solder is slightly longer.

Results/Benefits Induction heating provides:

• Hands-free heating that involves no operator skill for

manufacturing, lends itself well to automation.

• Solder controlled by preforms, no excess left on board.

• Good solder flow without over heating the board and

damaging adjacent circuits and components.

Soldering circuit boards

Related Content

induction brazing SS steel by handheld induction coil

induction melting silicon and steel

magnesium oxide acidic furnace for induction melting glass

induction preheating gas pipeline by full air cooled clamp induction coil and DSP induction heater

induction melting with Titanium alloy pot by customized induction coil

induction melting aluminium for casting wire wheel

induction heating steel plate by pancake induction coil

induction heating steel knife

Newest Comment

No Comment

Post Comment