Induction Sintering copper powder

Views Send Enquiry

Objective Sintering copper powder to a stainless steel shaft

Material Steel shaft & shell assembly, approx 2” (50.8mm) diameter, 2” (50.8mm) tall, copper powder

Temperature 1600 ºF (871 ºC)

Frequency 54 kHz

Equipment • Power of 45kW induction heating system, equipped with a remote workhead containing eight 1.0 μF capacitors for a total of 8.0 μF.

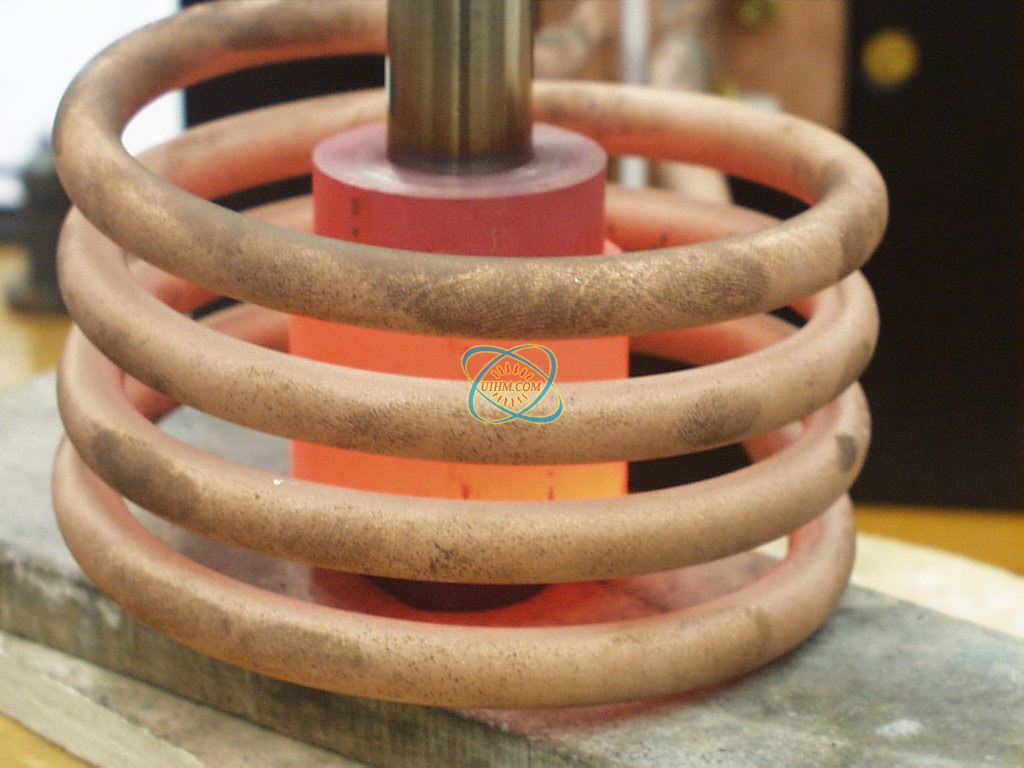

• An induction heating coil designed and developed specifically for this application.

Process A four-turn helical coil is used to heat the assembly for five minutes. This provides slow, even heat for good penetration through the shell into the powder.

Results/Benefits Induction heating provides:

• Even heat through the shell to sinter the powder.

• A method that is easily integrated into an automated production line. The design may be adapted to accommodate the indexed heating of several assemblies at the same time.

• Hand- free operation that involves no operator skill for manufacturing.

Sintering copper powder

Related Content

induction brazing SS steel by handheld induction coil

induction melting silicon and steel

magnesium oxide acidic furnace for induction melting glass

induction preheating gas pipeline by full air cooled clamp induction coil and DSP induction heater

induction melting with Titanium alloy pot by customized induction coil

induction melting aluminium for casting wire wheel

induction heating steel plate by pancake induction coil

induction heating steel knife

Hot

induction brazing SS steel by handheld induction coil

induction brazing shoe mold

induction brazing drill bit of transformer

customized RF induction heater for brazing works

induction brazing stator

water cooled flexible handheld induction coil for heating SS steel pipe

water cooled flexible handheld induction coil for heating SS steel pipes

UHF handheld induction heater for brazing copper

Newest Comment

No Comment

Post Comment