Induction Heating producing Aluminum

2013/5/16 Views

Barmet Aluminum Corporation produces 300 million lbs. of aluminum sheet per year and has plants located in

Barmet Aluminum Corporation produces 300 million lbs. of aluminum sheet per year and has plants located inUhrichville, Ohio and Carson City, California. At the plants, scrap and ingots are melted in gas-fired reverberatory

furnaces and the molten aluminum adjusted for chemistry in reverberatory holding furnaces.

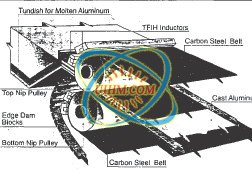

The molten aluminum is poured into a Hazelett twin-belt caster to produce a continuous strip.

The strip is fed directly into a hot-strip mill and then into a cold mill where it is reduced to sheetgauges. The coiled sheet product is then batch annealed in electric resistance heated furnaces. After annealing the product is tension

levelled and shipped to customers.

Next: induciton heating technology reviewPrevious: induction tempering of steel

Down Attachment

- DownloadAttach1: Induction Heating producing Aluminum.pdf Clicks

Good

Bad

Newest Comment

No Comment

Post Comment