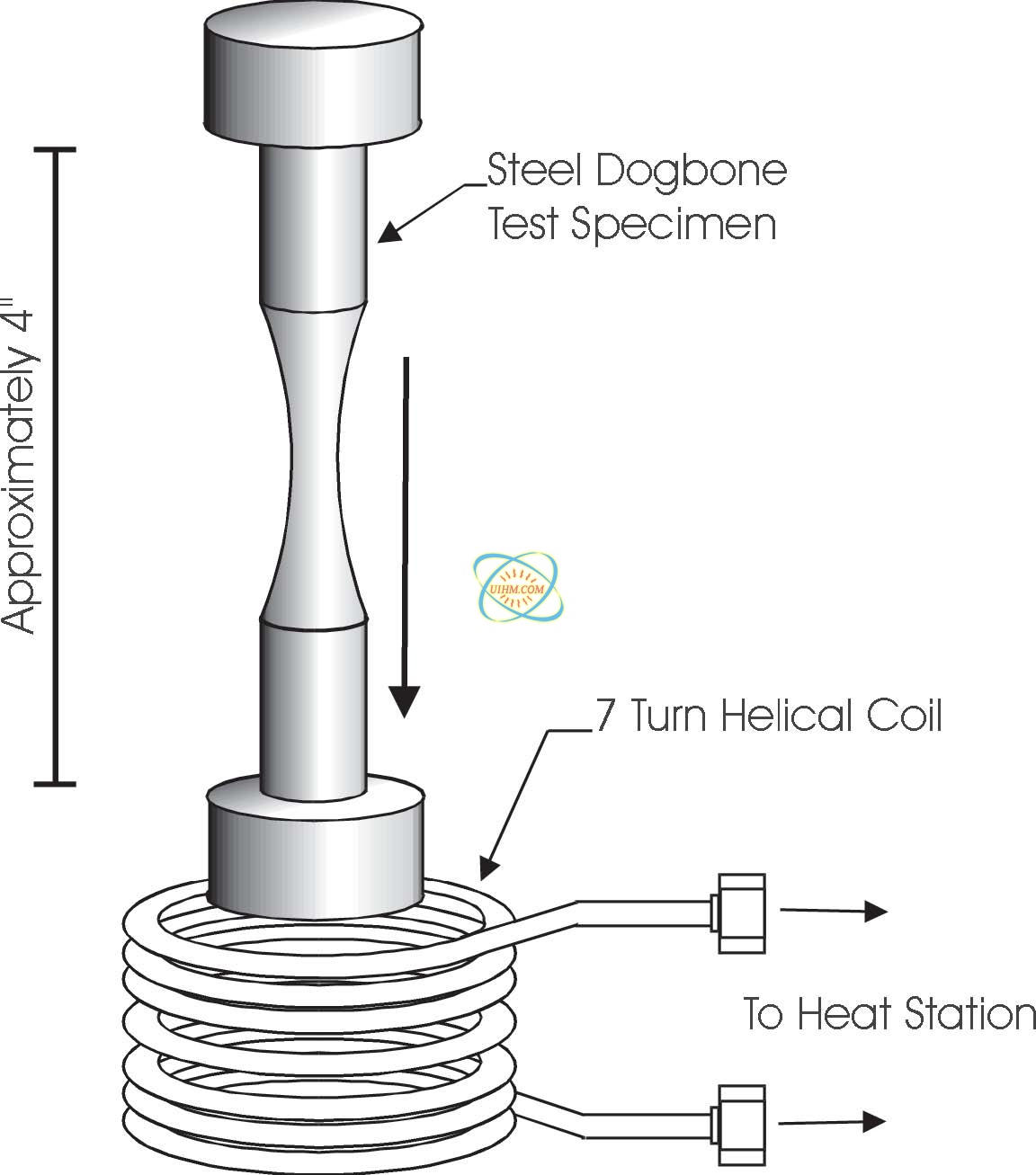

Induction Heating Steel Dogbone Specimen

Views Send Enquiry

Objective: To heat a magnetic steel dogbone specimen to 12000F as quickly as possible and sustained for tensile testing. Heating should take place using a helical coil placed square in relation to the long axis of the gage area. Also, thermal and mechanical loading need to be controlled through the use of a temperature sensor output.

Material: 1008 Steel Dogbone Test Specimen measuring 4 3/4″ long, 11/16″ in diameter at the ends, and 0.406″ in diameter in the middle of the gage section.

Temperature: 12000F

Application: The UIHM Laboratory Staff chose to use the Power of 15KW,15KW output solid state induction power supply along with a seven (7) turn helical coil, a Mirage Infrared Thermometer, and a 4-20 mA input device for enhanced voltage ramp to achieve the following results:

# 12000F was reached throughout the gage area in 6.1 seconds.

# Temperature was sustained using the closed loop system provided by the Mirage Infrared Thermometer.

# Even and uniform heating was achieved through the use of the seven (7) turn helical coil.

Equipment: Power of 15KW,15kW output solid state induction power supply including one (1) remote heat station containing two (2) capacitors totaling 0.66 µF, a seven (7) turn helical coil with a 1 1/4″ ID and measuring 1 1/2″ OAL, a 4-20 mA output device to facilitate voltage ramping, and an optical thermometer.

Frequency: 231 kHz

Heating Dogbone Specimen

Related Content

induction brazing SS steel by handheld induction coil

induction melting silicon and steel

magnesium oxide acidic furnace for induction melting glass

induction preheating gas pipeline by full air cooled clamp induction coil and DSP induction heater

induction melting with Titanium alloy pot by customized induction coil

induction melting aluminium for casting wire wheel

induction heating steel plate by pancake induction coil

induction heating steel knife

Hot

induction painting after induction bending for pipelines

induction heating steel plate

induction remove copper from aluminium

induction heating stator frame

induction heating graphite mould

difference between induction heating inner surface and outside surface of steel ring

induction heating steel pot bottom

induction heating for heat preservation

Newest Comment

No Comment

Post Comment