Induction Forging Inconel Billets

Views Send Enquiry

Objective To heat inconel billets to 2050°F (1121.1ºC) for a forging process.

Material Small inconel billets 0.39” OD, 0.7” length (.99mm OD, 17.8mm length) with ceramic crucible 1.0” OD, 0.7” ID, 1.4” length (25.4mm OD, 17.8mm ID, 35.6mm length); large inconel billets 0.5” OD, 1.0” length (12.7mm OD, 25.4mm length) with ceramic crucible 1.25” OD, 0.87” ID, 1.37” length (31.8mm OD, 22.1mm ID, 34.8mm length)

Temperature 2050°F (1121.1ºC)

Frequency 226 kHz

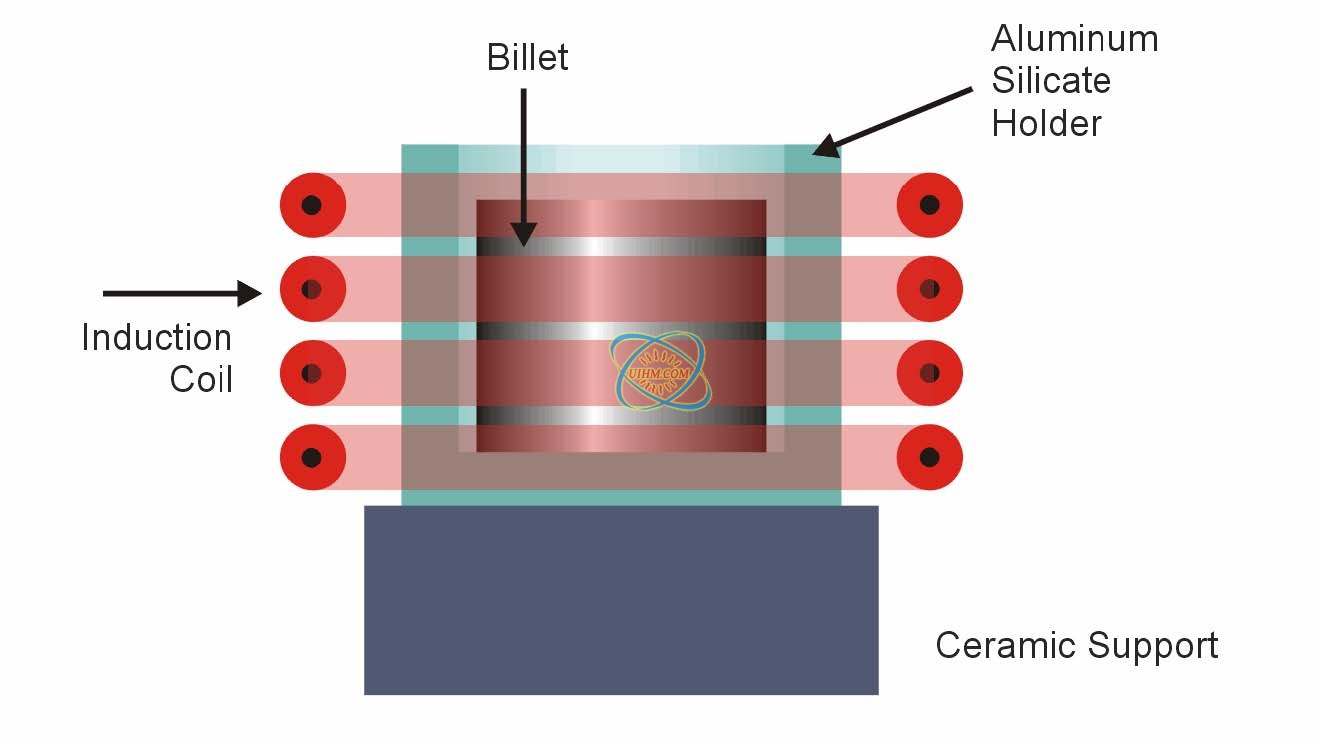

Equipment • Power of 20kW induction heating system equipped with a remote workhead.

• An induction heating coil designed and developed

specifically for this application.

Process A four-turn helical coil is used to deliver uniform heat to the inconel billets. Both size billets heat to 2050°F (1121.1ºC) within 12 seconds.

Results/Benefits Induction heating provides:

• Uniform and repeatable results

• Flameless

Forging Inconel Billets

Related Content

induction brazing SS steel by handheld induction coil

induction melting silicon and steel

magnesium oxide acidic furnace for induction melting glass

induction preheating gas pipeline by full air cooled clamp induction coil and DSP induction heater

induction melting with Titanium alloy pot by customized induction coil

induction melting aluminium for casting wire wheel

induction heating steel plate by pancake induction coil

induction heating steel knife

Hot

MF auto feed induction forging system

MF induction heater for forging work

induction forging long steel rods by MF machine

auto feed induction forging system

customized MF induction heater for forging steel rods

induction forging steel rods with series connection induction coil

induction forging steel rods by MF induction heater

induction forging steel rods

Newest Comment

No Comment

Post Comment