Induction Coating Aluminum

Views Send Enquiry

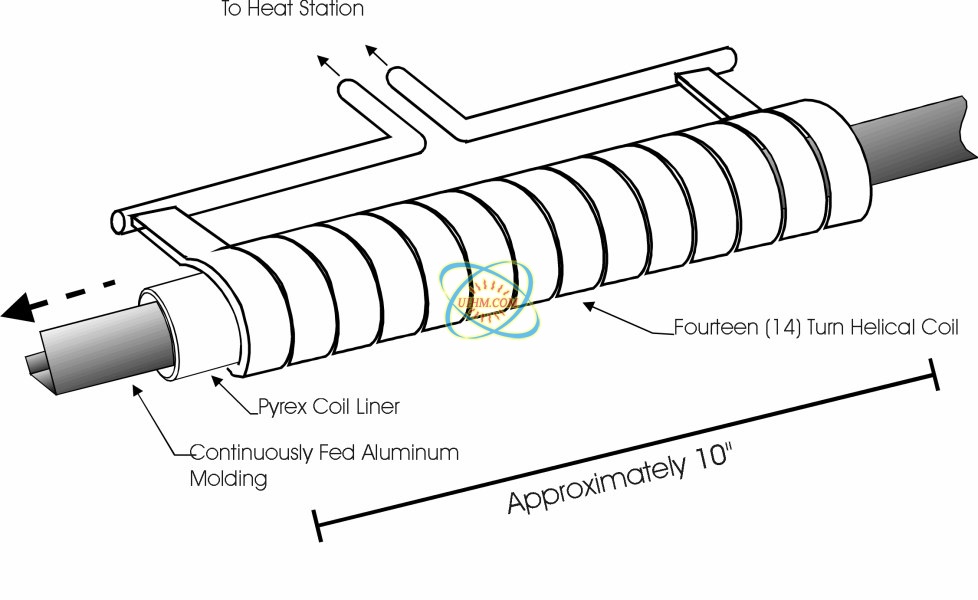

Objective To heat an aluminum molding shape in order to activate an adhesive coating prior to applying the vinyl

Material Aluminum molding folded from a flat sheet measuring 2″ wide and 0.03″ thick. The final form measures 5/8″ by 1″

Temperature 500ºF

Frequency 118 kHz

Equipment Power of 60kW power supply including a remote heat station holding three capacitors totaling 0.83 μF. A

specially designed 14-turn helical coil made from 1/2″ flattened copper tube.

Process Processing is to be continuous at a rate over 20 feet per minute with the temperature reaching 500°F. The aluminum is formed from a roll of flat sheet, after which the molding is coated with adhesive and is sent through an induction coil. Warping of the molding must be kept to an absolute minimum throughout the heating process.

Results Heating to 500°F is accomplished through the use of the unique coil; molding is continuously processed at a rate over 20 feet per minute. Due to the even heating produced through induction, warping of the aluminum molding was kept to a minimum.

Related Content

Air Cooled clamp coil (half-open coil) for preheating gas pipeline

induction coating by air cooled clamp induction coil

Remove plastic coating from steel tubes by Induction Heating

Releasing Fixture by Induction Heating

U shape air cooled induction coil by UM-100C-HF for pipeline preheating

induction quenching with custom-design inductor

induction brazing diamond segment

induction brass soldering copper plate_2

Hot

install air-cooled clamp coil for preheating pipeline

Air Cooled clamp coil (half-open coil) for preheating gas pipeline

induction vacuum coating with multi UM-DSP induction heater

induction coating by air cooled clamp induction coil

induction preheating D5000mm end ring for welding by 2 UM-DSP80A-HF at the same time

induction preheating D1219mm pipeline for welding by UM-DSB80AB-MF air cooled induction heater and i

induction preheating and heat treatment for 18Ton control valve of 600MW turbine

induction preheating and heat treatment after welding for 600MW turbine

Newest Comment

No Comment

Post Comment