Induction Forging Inconel Billets

Views Send Enquiry

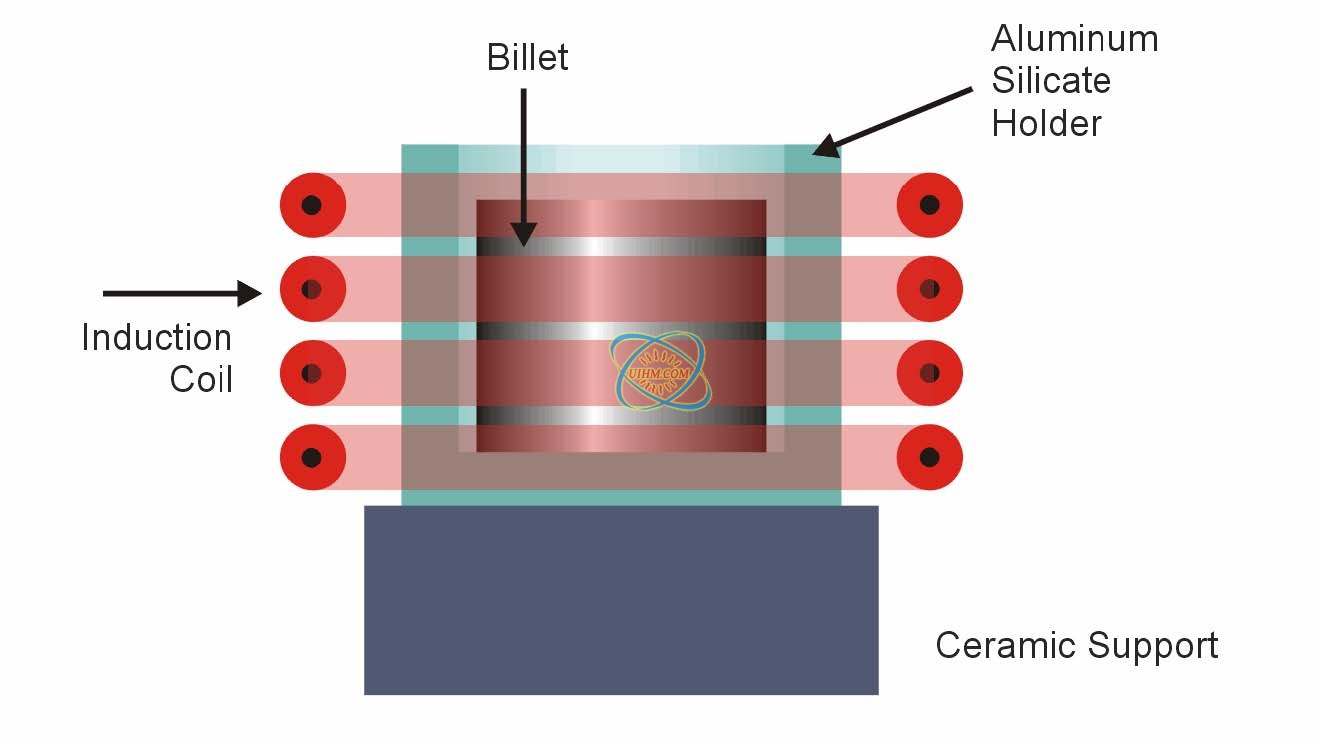

Objective To heat inconel billets to 2050°F (1121.1ºC) for a forging process.

Material Small inconel billets 0.39” OD, 0.7” length (.99mm OD, 17.8mm length) with ceramic crucible 1.0” OD, 0.7” ID, 1.4” length (25.4mm OD, 17.8mm ID, 35.6mm length); large inconel billets 0.5” OD, 1.0” length (12.7mm OD, 25.4mm length) with ceramic crucible 1.25” OD, 0.87” ID, 1.37” length (31.8mm OD, 22.1mm ID, 34.8mm length)

Temperature 2050°F (1121.1ºC)

Frequency 226 kHz

Equipment • Power of 20kW induction heating system equipped with a remote workhead.

• An induction heating coil designed and developed

specifically for this application.

Process A four-turn helical coil is used to deliver uniform heat to the inconel billets. Both size billets heat to 2050°F (1121.1ºC) within 12 seconds.

Results/Benefits Induction heating provides:

• Uniform and repeatable results

• Flameless

Forging Inconel Billets

Related Content

Air Cooled clamp coil (half-open coil) for preheating gas pipeline

induction coating by air cooled clamp induction coil

Remove plastic coating from steel tubes by Induction Heating

Releasing Fixture by Induction Heating

U shape air cooled induction coil by UM-100C-HF for pipeline preheating

induction quenching with custom-design inductor

induction brazing diamond segment

induction brass soldering copper plate_2

Hot

induction forging

induction forging steel billets

medium frequency induction forging steel rods (steel bars)

induction forging steel rods (steel bars)

medium frequeny induction forging steel billets with pneumatic feed system

induction forging steel rods_3

induction forging steel rods_2

induction forging steel rods_1

Newest Comment

No Comment

Post Comment