induction Vacuum Brazing

2013-04-08 Views

5. KEY PARAMETERS OF BRAZING

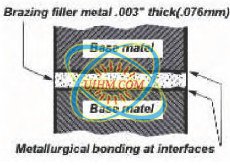

The quality of brazed joint depends strongly on the combination of filler and base materials and the processing conditions that are used. Other factors which influence the joints are condition of the solid surfaces i.e. nature of the oxides and other coatings, surface roughness, etc., temperature gradients, metallurgical reactions between the filler and parent materials and chemical reactions with fluxes in case they are used. The manner and extent of the flow of the molten filler into the joint is also a key aspect of joining with fillers. This is influenced by dimensions of the joint, surface conditions of the components, joint gap or clearance between the joints, surface energy/surface tension and wetting properties and spread characteristics of the filler metal.

6. STEPS OF BRAZING

Brazed joint makes itself which ensures the distribution of filler metal into the joint. The real skill lies in the design and engineering of the joint. This may prove fruitless if correct brazing procedures not followed. These procedures are simple to perform and should not be exclued from the brazing schedule for realizing sound, strong and neat appearing joints. These procedures are common to all methods with some variations in one method to other. Here various steps are mentioned with respect to vacuum brazing process.

The quality of brazed joint depends strongly on the combination of filler and base materials and the processing conditions that are used. Other factors which influence the joints are condition of the solid surfaces i.e. nature of the oxides and other coatings, surface roughness, etc., temperature gradients, metallurgical reactions between the filler and parent materials and chemical reactions with fluxes in case they are used. The manner and extent of the flow of the molten filler into the joint is also a key aspect of joining with fillers. This is influenced by dimensions of the joint, surface conditions of the components, joint gap or clearance between the joints, surface energy/surface tension and wetting properties and spread characteristics of the filler metal.

6. STEPS OF BRAZING

Brazed joint makes itself which ensures the distribution of filler metal into the joint. The real skill lies in the design and engineering of the joint. This may prove fruitless if correct brazing procedures not followed. These procedures are simple to perform and should not be exclued from the brazing schedule for realizing sound, strong and neat appearing joints. These procedures are common to all methods with some variations in one method to other. Here various steps are mentioned with respect to vacuum brazing process.

Next: UM-25 Series CircuitPrevious: Theory of Heating by Induction

Down Attachment

- DownloadAttach1: vacuum brazing.pdf - Induction Heating.pdf Clicks

Good

Bad