Induction Annealing brass wire

Views Send Enquiry

Objective Continuously anneal a brass wire used in electric motors at a rate of 16.4 yds (15m) per minute to eliminate work hardening caused during the drawing process.

Material Square copper wire 0.06” (1.7mm) dia., temperature indicating paint

Temperature 842 ºF (450 ºC)

Frequency 90 kHz

Equipment • 40kW induction heating system, equipped with a remote workhead containing eight 1.0μF capacitors for a total of 8.0μF

• An induction heating coil designed and developed specifically for this application.

Process A twelve turn helical coil is used. A ceramic tube is placed inside the coil to isolate the copper wire from the copper coil and to allow the copper wire to flow smoothly through the coil.

Power runs continuously to anneal at a rate of 16.4 yds (15m) per minute.

Results/Benefits Induction heating provides:

• Hands-free heating that involves no operator skill for manufacturing

• Flameless process

• Ideal for in-line production processes

copper-wire-passing-through-coil

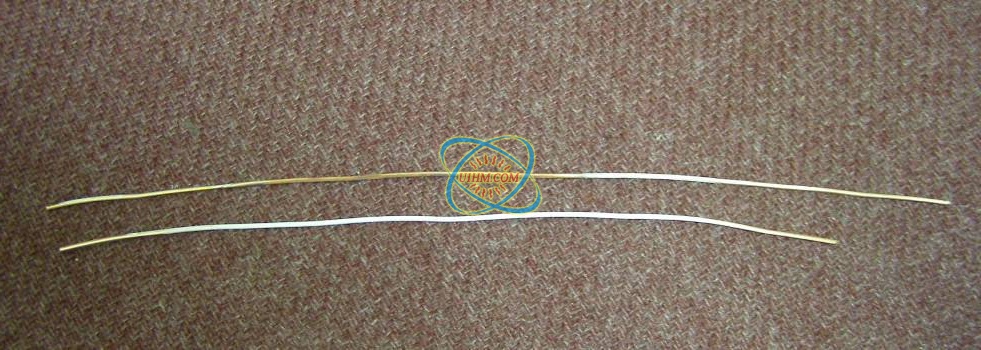

annealed-wire

Related Content

Air Cooled clamp coil (half-open coil) for preheating gas pipeline

induction coating by air cooled clamp induction coil

Remove plastic coating from steel tubes by Induction Heating

Releasing Fixture by Induction Heating

U shape air cooled induction coil by UM-100C-HF for pipeline preheating

induction quenching with custom-design inductor

induction brazing diamond segment

induction brass soldering copper plate_2

Hot

induction annealing for stainless pipe

induction annealing umbrella ribs by 60KW induction heater (UM-60AB-UHF)

induction annealing steel wire online

induction annealing steel umbrella ribs by 40KW induction heater (UM-40AB-HF)

induction annealing by horizontal type induction heater

induction annealing rod steel (steel bar)

induction annealing water channel

UHF induction annealing

Newest Comment

No Comment

Post Comment